Transforming manufacturing facilities with smart IFM solutions

Technical asset management

Technical asset management

Service: Technical asset management

Maintenance Service | Energy Saving | Digital Solutions

TTI is a leading tool manufacturer in Dongguan. Faced with rising maintenance demands and operational inefficiencies, the client needed a smart facilities management solution that could optimize performance while reducing costs.

To address these challenges, Aden implemented a smart Integrated Facilities Management (IFM) strategy, including digital twin technology and real-time monitoring systems, ensuring seamless operations and long-term sustainability.

Let’s explore how Aden’s smart IFM solutions delivered measurable improvements in equipment uptime, energy savings, and operational reliability.

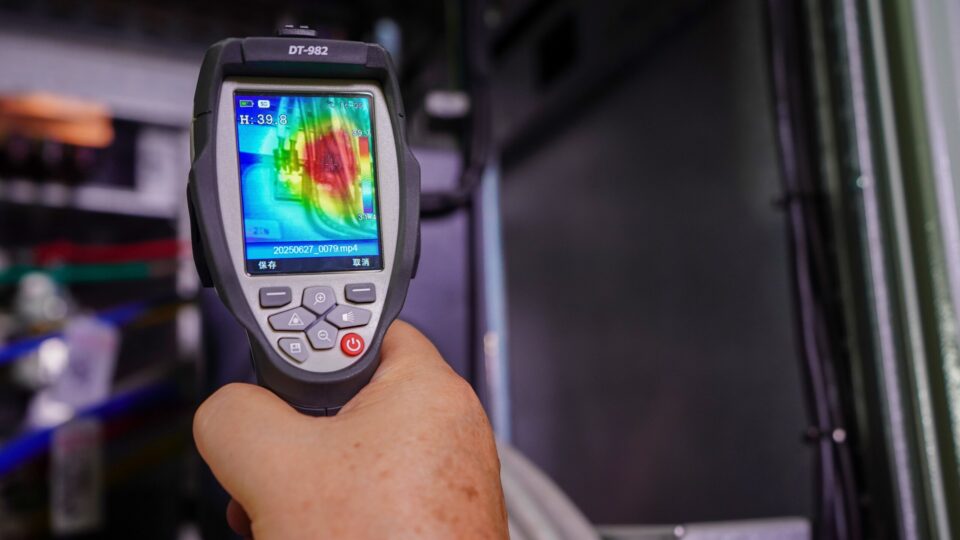

Aden’s approach centered on digitization and predictive maintenance to transform the facility’s operations.

Aden Services provided a comprehensive range of services to ensure the facility’s optimal performance. The HVAC system underwent annual maintenance to guarantee efficiency and reliability, while the power supply and distribution systems were managed with regular upkeep to maintain uninterrupted operations. The compressed air system was equipped with real-time monitoring and ambitious improvement plans, leading to significant cost savings. Additionally, the team handled all aspects of building maintenance, including walls, doors, windows, roof structures, and drainage systems, as well as maintaining a robust firefighting system to ensure safety compliance.

Aden deployed an on-site team of 28 dedicated professionals, complemented by remote support from experts in Shenzhen, Guangzhou, and Shanghai. The entire operation was built on a fully digital model, leveraging digital twin technology from contract initiation through daily operations. This approach ensured transparency, efficiency, and data-driven decision-making at every stage of the project.

1. Operational Efficiency:

2. Cost and Energy Savings:

3. Client Satisfaction:

This project demonstrates how smart IFM solutions can breathe new life into aging industrial facilities. Aden’s combination of on-site expertise, digital tools, and energy-saving initiatives delivered measurable results, proving that even the most challenging environments can achieve operational excellence.

Looking to transform your facility? Need more information about our solutions?

We’re here for you!