The facility maintenance industry is undergoing a transformative shift, driven by advancements in intelligent technology. From real-time diagnostics to automated repairs, these innovations are revolutionizing how businesses maintain their assets—boosting efficiency, reducing downtime, and cutting costs.

Here’s how intelligent solutions are reshaping the future of facility maintenance.

Intelligent diagnosis: the proactive approach to facility health

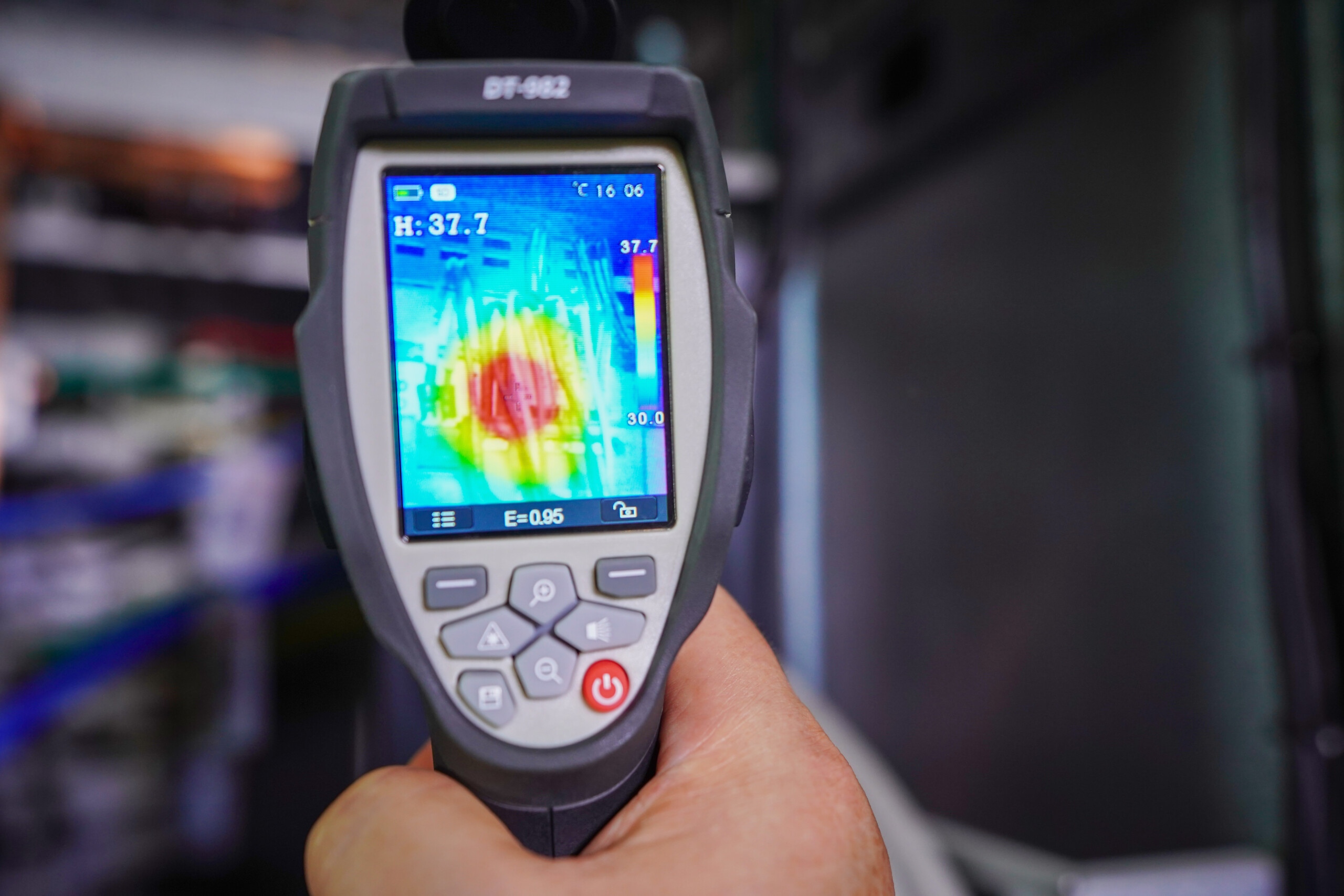

Modern facilities are increasingly adopting intelligent diagnostic tools to monitor equipment health with unprecedented precision. Smart sensors, for instance, now capture over 95% of critical operational data in real time—a 30%

improvement over traditional methods. These sensors track vital metrics like vibration frequency, temperature fluctuations, and pressure changes, providing a comprehensive view of equipment performance.

Machine learning algorithms further enhance diagnostics by analyzing historical data to predict failures before they occur. Leading manufacturers report that AI-driven systems have increased their failure prediction accuracy from 60% to 85%. For example, if a machine’s vibration exceeds normal levels by 15% for three consecutive days, the system triggers an alert—at least two days earlier than manual inspections—preventing costly unplanned downtime.

Big data analytics adds another layer of insight by identifying hidden patterns. Research in smart buildings reveals that 70% of facility failures correlate with environmental factors and usage trends. Air conditioners, for instance, experience 40% more failures during peak summer months and 35% more during high-usage periods. Armed with this knowledge, maintenance teams can implement targeted preventive measures, significantly reducing failure rates.

Intelligent repair: faster, smarter, and more efficient

When issues arise, intelligent repair technologies ensure swift and precise resolutions. Automated tools, such as welding robots in automotive factories, complete repairs 60% faster than manual labor while reducing defects from 8% to under 3%. This not only speeds up the repair process but also ensures higher-quality outcomes.

Remote repair solutions are also gaining traction, particularly in industries like power maintenance. Technicians can now resolve over 70% of minor issues remotely in under 30 minutes, compared to the previous two-hour average.

Using high-definition cameras and real-time data, experts guide on-site teams through complex fixes—eliminating travel time and minimizing disruptions. In one case, a remote team restored a substation in just 15 minutes, preventing a potential blackout.

Smart maintenance management systems further streamline operations. In logistics warehouses, these systems have accelerated work order processing by 55% and improved resource allocation by 40%.

By analyzing the nature and urgency of a problem, the system dispatches the nearest qualified technician and ensures parts are ready—reducing repair times dramatically. For example, a loose shelf can be flagged, assigned to a worker, and resolved within five minutes.

Overcoming challenges on the path to intelligent maintenance

While the benefits are clear, adopting intelligent maintenance solutions comes with challenges. The initial investment can be significant, with full-system deployment costing 15–20% of a facility’s total budget. However, as technology matures and adoption grows, costs are projected to drop by a third within 3–5 years, making it more accessible to small and medium-sized businesses.

Data security remains a critical concern, especially with the rise of cyber threats. Last year, data breaches in facility maintenance cost an average of 5 million yuan per incident. To mitigate risks, 80% of companies are increasing investments in cybersecurity, allocating 25% of their IT budgets to measures like encryption and access controls.

Another hurdle is the skills gap. Currently, only 18% of facility maintenance workers are trained in intelligent technologies, while demand for these skills is 30–40% higher. To bridge this gap, businesses are partnering with educational institutions to develop specialized training programs. The goal is to equip over 30% of the workforce with these skills within 2–3 years.

The future: smarter facilities and sustainable growth

Despite these challenges, the future of intelligent facility maintenance is bright. With advancements in 5G, AI, and the Internet of Things (IoT), facilities are poised to operate 50% more efficiently with 50% fewer breakdowns within five years. This evolution will not only enhance operational performance but also support sustainable growth across industries.

As intelligent dianosis and repair become the norm, businesses that embrace these technologies today will lead the charge into a smarter, more efficient era of facility maintenance. The question isn’t whether to adopt these solutions—it’s how quickly you can integrate them to stay ahead of the curve.