Once viewed as a cost center, facility management (FM) is rapidly evolving into a data-driven engine for business performance. The digital transformation of the built environment—powered by big data and analytics—is unlocking new levels of efficiency, sustainability, and strategic value.

By harnessing real-time and historical data, FM teams are no longer just responding to problems—they’re anticipating them, optimizing operations, and shaping long-term outcomes. Below, we explore three of the most impactful ways big data is redefining facility management—with proven results and measurable ROI.

1. Smart Energy Management: Real-Time Savings, Continuous Optimization

Energy remains one of the largest operational expenses in facility management. Traditional practices—relying on static reports and manual meter readings—often leave savings untapped and issues unnoticed.

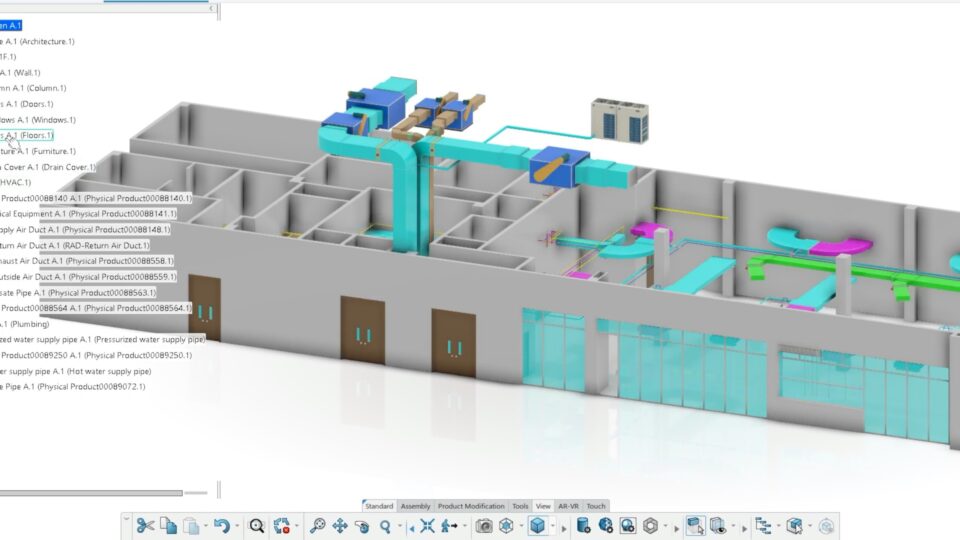

Today, data-driven energy management changes the game. By combining smart meters, real-time monitoring, historical benchmarks, and AI-powered control systems, facilities can identify anomalies, forecast loads, and respond to dynamic electricity pricing automatically.

Proven impact:

- Smart HVAC controls combined with AI reduced annual electricity costs by ¥1.2 million—a savings of 18%.

- Load forecasting algorithms cut peak demand charges in factories by 23%.

- Data-optimized cooling systems improved Power Usage Effectiveness (PUE) from 1.6 to 1.3, saving over 4 million kWh per year.

These aren’t static improvements—they’re part of self-learning systems that adapt to seasonal changes, occupancy patterns, and equipment aging. With granular insight and automation, energy management becomes a continuous performance lever.

2. Predictive Maintenance: From Downtime to Uptime-as-a-Service

Conventional maintenance swings between two costly extremes: servicing assets too early or reacting only when they break. Big data offers a smarter approach—predicting equipment failure before it happens.

By collecting sensor data (vibration, temperature, energy use) and correlating it with historical patterns, predictive models can flag early warning signs and optimize maintenance schedules.

Real-world benefits:

- Conveyor systems in airports achieved 92% fault prediction accuracy, enabling 70% faster repairs.

- In hospitals, proactive part replacements in HVAC systems avoided costly downtime and saved ¥800K annually.

- In manufacturing, predictive models reduced breakdowns by 45% and boosted maintenance efficiency by 60%.

The result is longer asset lifespans, fewer service disruptions, and more strategic maintenance contracts. In fact, predictive insights are paving the way for “performance-based” service models—where providers are paid based on uptime, not time on-site.

3. Space Optimization: Unlocking Hidden Value in the Built Environment

Space is often an underleveraged asset. Big data analytics—powered by occupancy sensors, Wi-Fi tracking, and heatmap visualizations—now allow FM teams to understand how spaces are truly used, and how to make them work harder.

Strategic outcomes:

- Offices using hot-desking analytics cut unused floor space by 30%, saving ¥5 million annually in rent.

- Retailers optimized store layouts with customer movement data, increasing premium-zone lease value by 25%.

- In logistics, AGV route optimization improved warehouse throughput by 40% and cut labor costs by 15%.

Space optimization isn’t just about cost—it’s also about experience. For example, data-driven redesigns of airport security checkpoints reduced passenger wait times by 35%, enhancing both efficiency and satisfaction.

Big Data Is More Than a Tool—It’s a Mindset Shift

Big data doesn’t just improve operations; it redefines the mission of facilities management. With the right digital infrastructure, FM leaders become strategic advisors—impacting cost structures, sustainability targets, employee experience, and even revenue.

The question for organizations is no longer whether to adopt big data in facilities, but how quickly they can build the capability. One thing is clear: in the future of FM, data isn’t a bonus—it’s a baseline.